We are Manufacturer, Supplier, Exporter (and also Servicing / Maintenance Services Provider) of Plate Heat Exchangers (PHE), Genuine Spares, Spare Parts from Pune, Maharashtra, India.

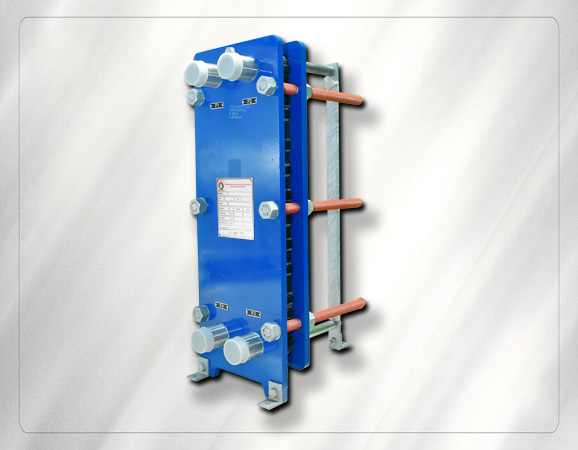

Our Eternitive® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. Innovativetechnologies and smart design make our standard plate heat exchangers a stellar investment and the go-to choice for standard duties.

We have one to one solutions for any brand of heat exchangers in the world and we customize each heat exchanger to meet your exact requirements. The versatile design and high thermal efficiency make them the perfect solution for a wide range of applications.

Eternitive Heat Transfer Solutions India Private Limited (EHTS) is a leader in heat transfer technology, offering reliable heat transfer solutions backed by 20 years of experience in the competitive Indian market. Our plate heat exchangers are designed to deliver resilience, dependability, and performance over their lifetime.

EHTS is ISO 9001:2015 certified and began as a distributor of leading global brands in plate heat exchangers. Our products serve various demanding applications in industries like steel, power, food and beverage, and chemical processing.

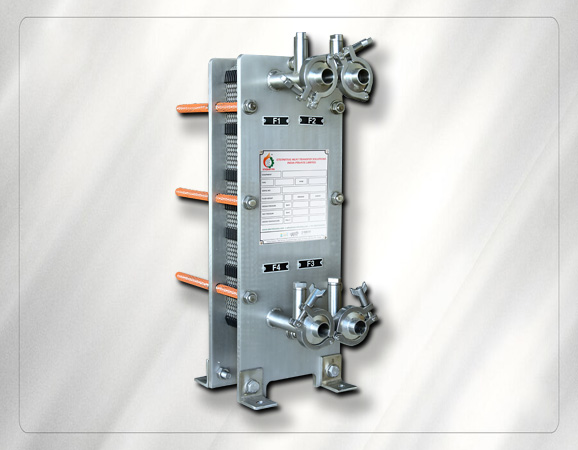

Our Eternitive® sanitary plate heat exchangers uses FDAcomplaint compliant materials and are designed to use in food, dairy, and beverage applications as well as otherapplications with strict sanitary requirements. We have the in-depth process knowledge and extensive experience needed to engineer hygienic, high - performance solutions.

EHTS designs and manufactures plate heat exchangers utilizing thin metal plates for effective heat transfer between fluids. These heat exchangers ensure minimal energy consumption while maximizing thermal efficiency, applicable for heating, cooling, heat recovery, condensation, and evaporation.

- HVAC industry

- Heavy industry

- Mining industry

- Sugar industry

- Biogas industry

- Chemical industry

- Pulp and paper industry

- Petrochemical industry

- Marine/offshore industry

- Dairy/food/beverage industry

- Industries with Sanitary requirements

- Frames designed according to FEA and PED 2014/68/EU

- (EN13445) and ASME sec VIII, Div.1 construction standards

- Plate materials: AISI 304/316, titanium, SMO, Hastelloy*

- Connections from DN25 to DN600 (1" to 24")

- Working temperatures from -20 °C to 180 °C

- Gasket materials: EPDM-HT, NBR-HT, Viton*

- Flow rates up to 7,200 m3/h (31,700 gpm)

- Other materials are available upon request

- Working pressure up to 35 bar (500 psi)

- Plate lengths up to 5.5 m (18 ft)

- Precise heat transfer with close temperature approach

- Cost-effective solutions with low maintenance costs

- High consistency with minimal fouling and wear

- Custom designs to meet specific customer requirements

- Experience the benefit of an individually customized solution that perfectly matches your requirements and lowers your energy consumption.

- High performance and a low pressure drop eliminate unnecessary burdens on your system and optimize overall system performance.

- We design single - pass solutions when possible, as they are the preferred choice for almost all duties. With all connections on the head you do not need to disconnect the heat exchanger from the piping to performinspection, cleaning, or service.

- The design results in a compact solution with a small footprint, simpleinstallation, and easy access for maintenance.

- Heat exchanger solutions that adhere to the strict hygienic demands of the industries and complies with FDA material standards.

- Plate technology made to provide the highest output product quality.

- We ensure gentle media treatment during processing with precise flowcontrol, perfect temperature profiles, and the optimal residence time for all applications.

- Cladded or stainless-steel frames designed to be easily accessible for quick and trouble-free inspection, maintenance, or cleaning - including cleaning in place (CIP).

- Enjoy huge savings on your power consumption with our regenerativepasteurizers that can recycle up to 95% of the energy.